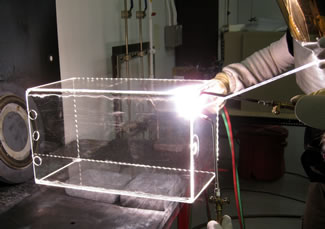

Welding...

Welding two pieces of glass together is very similar to the process used to join two pieces of metal via oxyacetylene or TIG welding. A rod of the material being joined (in our case, pure fused quartz) is fed into a liquid weld pool, which in turn is generated by a hand held torch. The oxyacetylene flame used for welding steel burns at almost 5,800° F, but introduces carbon and other elements to the work piece. The arc from a tungsten electrode on a TIG welder can reach 11,000° F, but only if the material being welded is electrically conductive.

Hydrogen and Oxygen have long been the gases used to produce a quartz-working flame. It's typical 5,072° flame temperature is lower than the others mentioned above; but with only water vapor as a byproduct, it is the perfect fuel for maintaining the high purity levels demanded in our quartz products.

As any journeyman welder will tell you, "Just about anybody can stick two pieces together with an hour's training." However getting the weld to be truly strong, not distort the pieces being joined, and have the finished product meet cosmetic requirements; that takes a skilled craftsman, and years of practice! The welding team here at Wacom Quartz each have between 15 to 35 years experience fabricating quartz.

As any journeyman welder will tell you, "Just about anybody can stick two pieces together with an hour's training." However getting the weld to be truly strong, not distort the pieces being joined, and have the finished product meet cosmetic requirements; that takes a skilled craftsman, and years of practice! The welding team here at Wacom Quartz each have between 15 to 35 years experience fabricating quartz.